Wireless technology is today changing the face of maintenance management. Every sector, be it educational, hospitality, manufacturing or service, the benefits of wireless technology is noticed everywhere.

Wireless technology can definitely bring about greater efficiency. When we look at how it transforms work, the impact is seem in every department.

With CMMS, technicians perform better as now they do not have to leave the field to close or receive orders.

For managers, the CMMS is an ultimate guide as it provides real-time data of assets and operations, on the basis of which the managers can talk to the technicians. These factors finally save a lot of cost for the organization.

Although the benefits are many, yet from a financial point of view, it’s never easy to adapt a new technology and transform the age old way of handling assets. Most managers face the challenge of implementing the software and replacing it with the traditional method.

Let’s look at some of the common challenges that stop managers from adapting the CMMS and let’s see how to overcome these hurdles:

Implementation of CMMS

CMMS is a boon to business, it comes with a host of features that can resolve any complex maintenance issue. While it is advantageous for companies, yet for most first time users, it looks too complicated. Most companies do not require all the feature they only need selective features that fit their business and thus are unable to decide if the software would really be of great value.

Well the solution to this is simple, before purchasing the software, communicate your needs to the CMMS vendor and select the product that only has the few selective features, applicable to your type of business. This way you can manage the cost of the software and also reap its benefit.

Fear of replacing Human Labor

Most companies think that CMMS would replace human labor, the conception is that by adapting the technology the dependency on human resource would reduce. Undoubtedly CMMS would make processes more defined and asset management more effective, but the truth is that CMMS can only schedule and track maintenance activities, the real job of physically maintaining the assets will still be done by technicians.

So in short, CMMS can extend the lifespan of assets, but it cannot execute the physical maintenance of assets. Managers need to understand this concept of technology and adapt it to grow their business.

Lack of Technical Awareness

This is one of the common reasons for not implementing the Preventive maintenance strategy. Even before understanding the software, there is a huge resistance on accepting it. This mindset is usually seen amongst senior employees who are quite comfortable with the manual ways of working and are too reluctant to accept any change.

Well to resolve this issue, managers need to first contact the CMMS team and organize a complete training of how to use the software. However endurance is highly expected from employees to go through this training as it would take few days to learn the software in detail.

Also during the training, ask all your questions. After the training, we guarantee that you will not only decide to purchase the software but you would enjoy working on it.

As a manager am sure you must be facing one of the above challenges. But knowing the CMMS will definitely add a great value to your business, all you need to do is keep these 7 important things in mind, before striking the deal.

- Identify your business needs – What are the features that can be used for your business

- Find the vendor that can offer you the features you need in the best price

- Ask for a demo of the features before purchase

- Research about the vendor and its reputation in the market

- Ask the vendor to implement the software

- Ask for a complete training on the software for all your people

- Check for after sales customer support service.

Conclusion

The thumb rule is to understand what you are purchasing and why. Once you have adapted the above points, you will be sure that you are making a right decision.

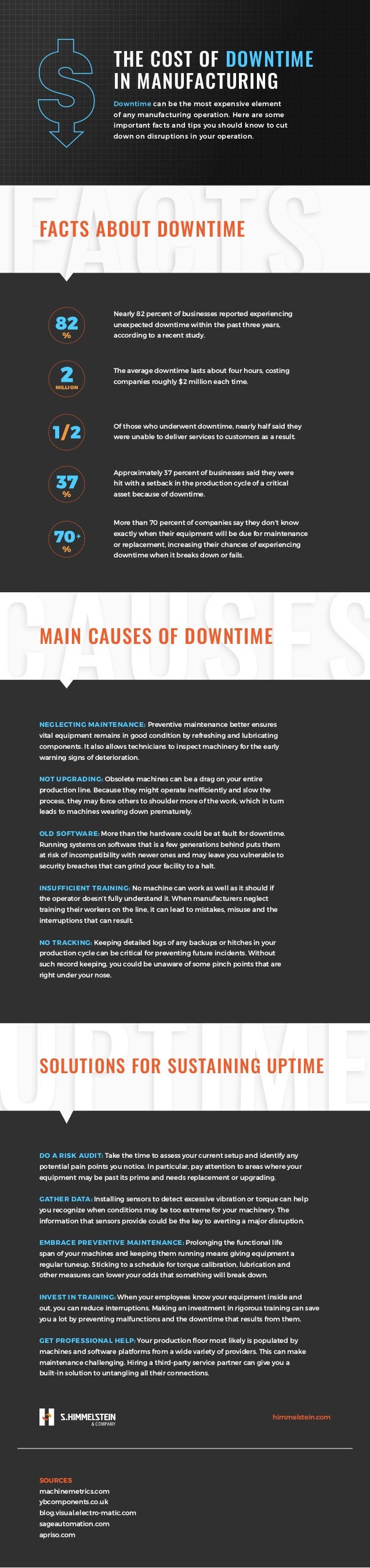

Guide created by S. Himmelstein & Company a leading manufacturer of torque tranducers