If you care about your employees’ and your business’ success, you want to keep your factory safe. This task is not always easy, especially during today’s pandemic caused by the novel coronavirus. However, you must continue to prioritize safety. Use these suggestions to evaluate your safety standards and then implement the ones that are most relevant to your situation.

Use Caution With Hazardous Materials

If you have machines that produce or use hazardous materials, such as plating tanks, you must exercise extreme caution around them. Store hazardous waste in containers that are rated to hold materials of their temperature or causticity. Avoid handling these materials, but if you must move them, wear gloves, safety goggles and any other available personal protective equipment.

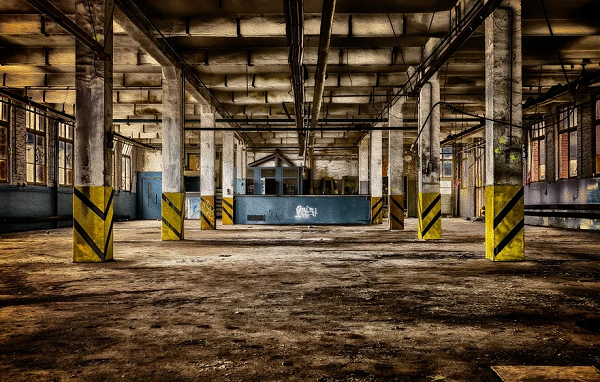

Keep the Floor Clean

Characters slipping on banana peels appear in every slapstick comedy show, but tripping is not a joke in the workplace. If someone trips while carrying expensive products or hazardous materials, the results can be costly or deadly. Additionally, people frequently suffer severe injuries from falls, particularly if they are elderly. To avoid these accidents, keep the floor clear of all packages, nails and other items that might make someone trip. Clean up all spills immediately, even if a little water just drips out of your water bottle.

Maintain Clear Exits

When life-threatening emergencies such as explosions and fires occur, the best way to ensure your safety is to get away from the source of the problem, especially if it is out of your control. Keep all exits clear and post directions for exiting the building above each doorway, particularly if your workspace has multiple floors. Never let boxes or cabinets block exits permanently.

While accidents can be rare if you are careful, they happen to everyone. Reduce the number of problems that occur and mitigate their impacts by following these guidelines.